Engraving Machine Software Download

What Makes Vision's Systems the Best Engraving Machines on the Market? We offer a solid line-up of small & large engraving machines: Our engraving systems come with industry leading features offered at competitive prices! Manufacturing engraving systems for over 35 years: We build quality made CNC machines with a proven track record, you can be confident when buying a Vision system! USA based knowledgeable tech support team: Based in our manufacturing building - machines, parts, technical engineers and more are readily available to assist in resolving any question or problems if needed. Join over 25,000 satisfied customers who own a Vision: With the most rugged and reliable low maintenance engraving machines in the market, our customer base can't help but grow! Many of our original systems are still in use today!

Machine Tool Industry. Laser Welding. LaserStar laser engraving software includes a comprehensive library of more than 100 True Type fonts. Download Our.

Made In The USA: American Made Engravers, Vision has been Proudly keeping Americans employed in the USA for over 35 years! What can you make and do with a Vision Engraver?: Metal, Wood, Plastic, Glass, Custom Signage, ADA Braille, Electrical Tags, Name Plates, Legend Plates, Asset Management, Parts Serialization, Parts Marking, Awards, Trophy Cups, Trophy Plates, Plaques, Watches, Pendants, Rings, Jewelry, ID Plates, Furniture, Dog Tags, Pens, Gift Personalization and More! We have a variety of machines to meet your needs & budget: 'The Vision System was lower in price compared to many others systems on the market.

Before you do anything else - be sure to take a serious look at Vision. You won't be disappointed.' - Don E, Engrave USA / Estes Machine Products, Inc. Fill out the form to get a list of machines with specs and info emailed to you today! Privacy Policy: Vision Engraving & Routing Systems does not collect any other personally identifiable information that you do not expressly provide.

We will never sell, rent or share your personal information, including your e-mail address, with any third parties for marketing purposes without your express permission. What applications can you make and materials you can work with on a Vision Engraving System? Metal Engraving, Wood Engraving, Plastic Engraving, Leather Engraving, Glass Engraving, Custom Signage, Electrical Tags, Name Plates, Legend Plates, Control Panels, Jewelry, Gift Personalization, Asset Management, Parts Serialization, Parts Marking, Cut-Outs, Parts Fabrication and More! 'The Vision System was lower in price compared to many others systems on the market. Before you do anything else - be sure to take a serious look at Vision.

You won't be disappointed.' Don E, Engrave USA / Estes Machine Products, Inc 'My Vision engraver has been truly been a work horse and a boon to my business. Having never had hands on experience before with this type of equipment, I found that the software was easy to learn and the engraver easy to operate. ' Teresa Russell / Visual deSigns 'We think it is the best thing since sliced bread. ' Don Powers / UMCDF.

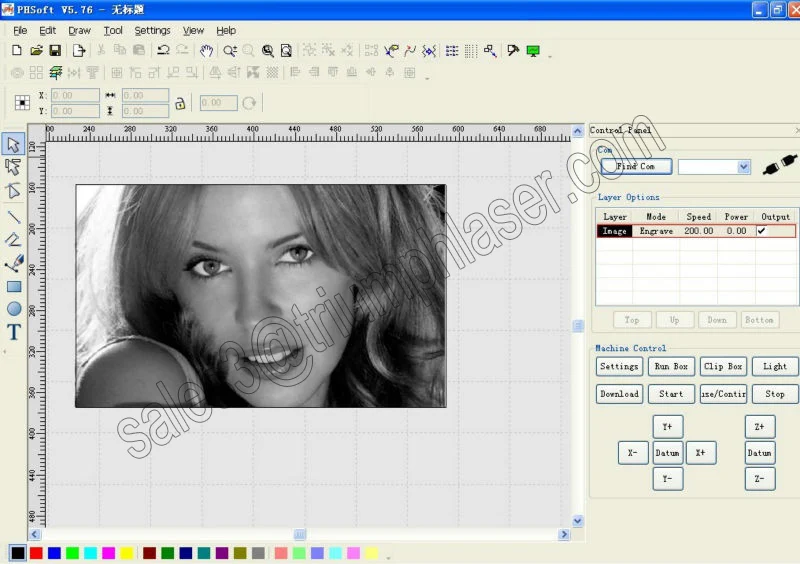

If you've read, where I added a 2 Watt Laser to a Shapeoko 2 you know something about the many things that can be made with a CNC controlled laser. The larger Shapeoko 2 laser is powerful and can accomplish many things, but it isn't great with really small engravings. It also takes a fair amount of setup - including to some degree restricting access to the room while the laser is running. I recently learned about a new, very affordable. This machine is a lot of fun!

U Marq Engraving Machine Software Download

It currently costs less than $90 U.S. Unlike my Shapeoko 2 based laser, it takes almost no setup time, there is no need to generate and then manipulate gcode files, and it can be set on the dining room table where you can be engraving within minutes! The, available from gearbest.com, includes a set of safety goggles.

You may want to obtain additional sets of goggles so that others can watch the engraving process, but this machine is also small enough that you could simply cover it with the shipping box while it runs - or build a box out of laser-safety acrylic. In this Instructable, I will demonstrate engraving on several different materials as well as show step-by-step what is involved in making and engraving and image.

The machine that I have is called a. It can produce an image that is approximately 38mm square. The image above will give you a rough idea of what the machine can do. You'll notice that 38 square millimeters is not very large, but also notice that even the small print is engraved well enough to be readable (even if you do need a magnifying glass to see it!) It is important to notice that a 72 point font is not 1' tall as it would be if printed from a desktop printer. Instead, it turns out to be about 7mm tall. Despite not being able to produce large engraving, the engraver produces excellent results in small images - something my Shapeoko 2 can't do without changing the belts. Setup involves two steps.

The first is installation of the driver that ships with the device on a micro SD card or which can be downloaded from the manufacturer. After the driver is installed the engraver program can be run from the same media. I've tested it on two different Windows 10 machines. CAVEAT: I had two initial problems.

The first one was images not printing completely because I had left a small piece of the shipping foam under the acrylic base plate. Make sure you don't make the same mistake.

The second problem that I had was also with images not printing to completion. This turned out to be a problem with my USB hub. When I replaced it with a new powered USB 2 hub, everything worked perfectly from there on out. The second part of setting up to engrave is to generate an image. This is easy. Use a program like Microsoft Paint to create a 512 x 512 pixel image.

Save the image as either a JPEG or a PNG file. You can now drag and drop your image into the Laser Engraver program. Once there you can rotate the image if necessary. Then click 'Send Image to Machine'. Once the image is stored in the laser engraver, it will 'draw' (not engrave) a rectangle around the area where the image will be engraved.

The rectangle traced will only include those parts of your image with engraving (non-whitespace) in it. As you can see from the images, chocolate can be engraved. Each of these engravings were done using only a single pass. The rose was done on a carmel filled Ghirardelli chocolate square (which had a slight crack prior to engraving). The other image is the back side of a Hershey bar segment. A second pass would produce a deeper image.

There was no change in the flavor/taste of the chocolate. Free beta software downloads. Many foods could be engraved.

I tried a slice of cheddar cheese and was surprised to see that it really only sweat where the laser drew on it. I had hoped for burn marks, but it may have had too much moisture. I also had no luck engraving on a marshmallow.:). How do you plan to run GRBL on this machine? I have been thinking about replacing the board with an arduino uno so that I can add a cooling fan, a work light, and maybe even another axis.

I have the arduino uno and the cnc shield. I've started building one from scratch but I threw that project out the window and replaced it with one that's built out of a flatbed scanner and a printer head drive assy. I haven't finished this yet, but when done it will be able to 'engrave' 10' wide (X) by 14' long (Y) 1 year ago. When I ordered mine, I didn't know anything about CNC of any kind other than I thought it was really fascinating. Now I've modified my carver so that it's got manual seek buttons. It took about a week of reading and watching youtube to figure out how exactly everything works. But the day I pulled it out of the box, I printed off about 10 items.

My wife and I used it this year to make christmas ornaments out of wood. It's as simple as. Select an image, drag it to the carver software, send to printer, check alignment/ centering of item then select your desired burn time, and hit start. It's very easy.